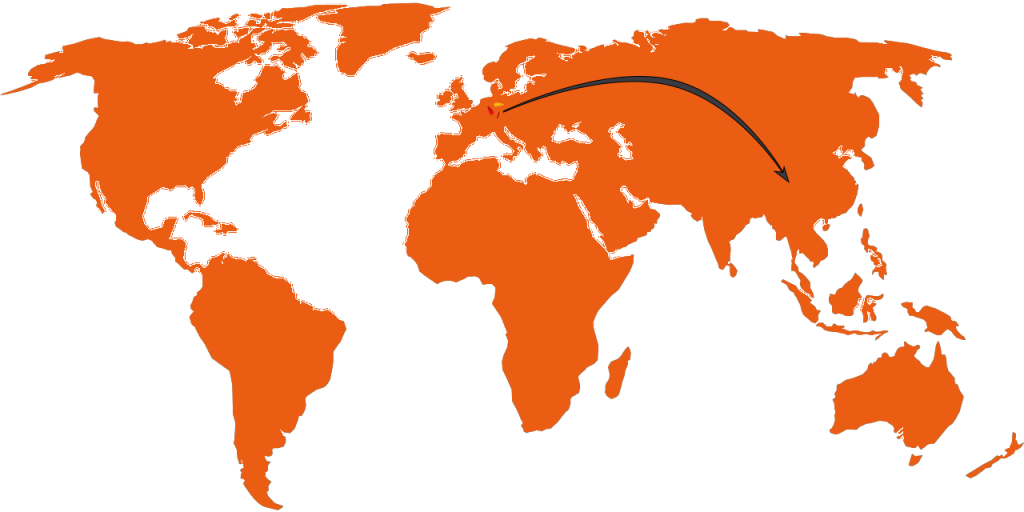

evoTrQ system on its way to China

Seven IPCs, three dashboard monitors, a laser station, four cameras and many other components were loaded into a truck a few weeks ago, which made its way halfway around the world to an automotive manufacturer in China. Because there – almost 8000 km away – the evoTrQ component tracking system is being installed in a press shop. A total of eight boxes weighing over 5 tons were loaded and sent on their way.

The evoTrQ component tracking system has made a considerable name for itself over the past few years. With its automation system, it helps many customers with quality inspection in their press shops. With the help of evoTrQ, huge amounts of production data can be collected and analyzed, which in turn can be used to reduce defective components, increase component quality and minimize overall expenses. For these reasons, evoTrQ is also becoming indispensable for the German automaker at its plant in China. There, the system has the task of tracking the material used in the press shop and the transparency of the process and material parameters at the component level. In addition, each component from the press shop is assigned to the chassis number.

Although evoTrQ can be installed directly in customers’ press shops, the number of parts and components to be supplied should not be underestimated. So before the individual components set off on their journey, precise packing was the order of the day. Even the smallest part of the scope of delivery had to be packed in such a way that it could be found again without any problems and could survive the journey without damage. For this occasion, even extra fireproof fabrics were made and placed over the transport boxes for protection.

In our picture gallery you will get further impressions of the big packing action of our evoTrQ system.

After weeks of travel, the components arrived safely at their future location in China. At the end of March, some of our colleagues will set off there and begin installation.

Press contact

-

Im Gewerbepark A52

D-93059 Regensburg - info[at]evopro-ag.de

- (+49) 941 899645-0

- (+49) 941 899 645-99