#sondermaschinenbau

Mechanical Engineering

#robotik

Automation

Mastering technology in all its facets is a challenge – we rise to it.

#robotik

Automation

Technological progress increasingly enables the transfer of complex work steps to automated systems.

PLC, robotics, sensor technology, actuator technology and mechanical engineering want to be harmonized.

Mastering technology in all its facets is a challenge – we rise to it.

#robotik

Automation

Mastering technology in all its facets is a challenge – we rise to it.

#robotik

Automation

Technological progress increasingly enables the transfer of complex work steps to automated systems.

PLC, robotics, sensor technology, actuator technology and mechanical engineering want to be harmonized.

Mastering technology in all its facets is a challenge – we rise to it.

Automotive

Technological progress increasingly enables the transfer of complex work steps to automated systems.

PLC, robotics, sensors, actuators and mechanical engineering want to be brought into harmony.

Engineering

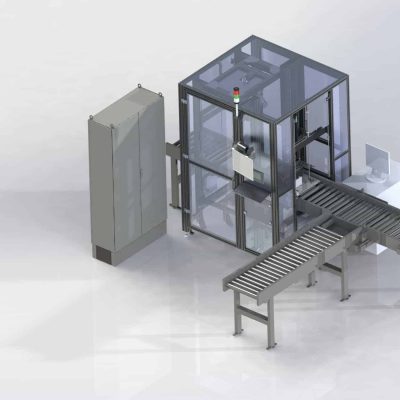

Ensuring and improving product quality

We advise and accompany you from the idea to the conception, development and implementation in order to harmonize your requirements and wishes together with what is technically feasible.

No matter what you are concerned about – humanisation, ensuring or improving product quality, rationalisation or the replacement or modernisation of old production equipment to ensure delivery capability – your satisfaction is our motivation.

Consulting and conception

- Feasibility studies

- Layout planning

- Specification creation

- GU project management

Development and construction

- Project management

- Cycle time analysis

- Risk assessment

- Electrical planning

- Pneumatics planning

- Documentation creation

- CE certification

Virtual Commissioning

- 3D simulation

- PLC simulation

- Robot simulation

- Digital twin

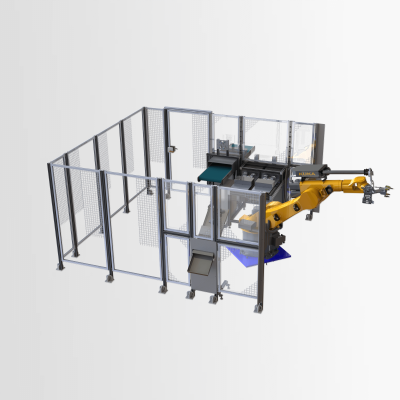

Robotics

More efficient manufacturing processes

With our know-how in the field of robotics we realize your production plant with robots of different manufacturers. Together with you, we will look for the system that best meets your requirements.

Not only solving challenging tasks with the help of robots, but also their interaction with humans are tasks that we are happy to take on.

application areas

- Assembly tasks

- Tool handling

- Palletizing

- Check, measure

- Marking, labeling

- Deburring

- Surface treatment

- Connection technologies

Robot types

- Project management

- Cycle time analysis

- Risk assessment

- Electrical planning

- Pneumatics planning

- Documentation creation

- CE certification

- Articulated / articulated arm robots (5, 6 and 7-axis systems)

- Palletizing robot

- SCARA robots

- Portal robot

- Collaborative robots

Installation, commissioning

After sales service

The heart of an industrial plant still beats in the PLC. Our developers see themselves not only as technicians, but above all as consultants and accompany you from the idea to the conception and development to the realization of your project.

We work out the plant sequence together with you and implement it in the PLC program code.

We ensure that man and machine communicate, optimise the processes and test the systems for stability and operability.

PLC systems and visualization

- Siemens SIMATIC, TIA, WinCC, WinCCflexible

- Beckhoff TwinCAT

- Bosch Rexroth ctrlX

- B&R Automation Studio

Areas of application

- Production systems

- Test systems and quality

- Robotic stations

EPlan

Project planning | Electrical installation

The basis of the electrical construction is the project planning of your system. We support you right from the start of the project in the selection of the required components and in the implementation of the safety technology.

In addition to your electrical installation, our designers integrate the system pneumatics into the overall circuit diagram.

Services

- Consulting and conception

- Risk assessment

- Component selection

- CAD construction

- Pneumatic connection

- Documentation creation

- CE certification

- Control cabinet construction, installation and assembly

Drive technology

Integration into plant control system

Due to the progressive mechatronization of our plants, drive technology is taking on an increasingly important role in plant engineering. Regardless of whether you use Siemens, Bosch-Rexroth or SEW servo technology, only an optimally parameterized controller will achieve maximum performance in your system.

We support you both in the selection of the drive technology and in the safety technology to be used for the controller systems. Whether dynamic controls or the simplest positioning controls, we integrate your servo drive system into the plant control system and parameterise it according to your requirements.

Servo drive system

- Siemens SINAMICS

- Bosch Rexroth ctrlX Drive

- SEW Motion Control