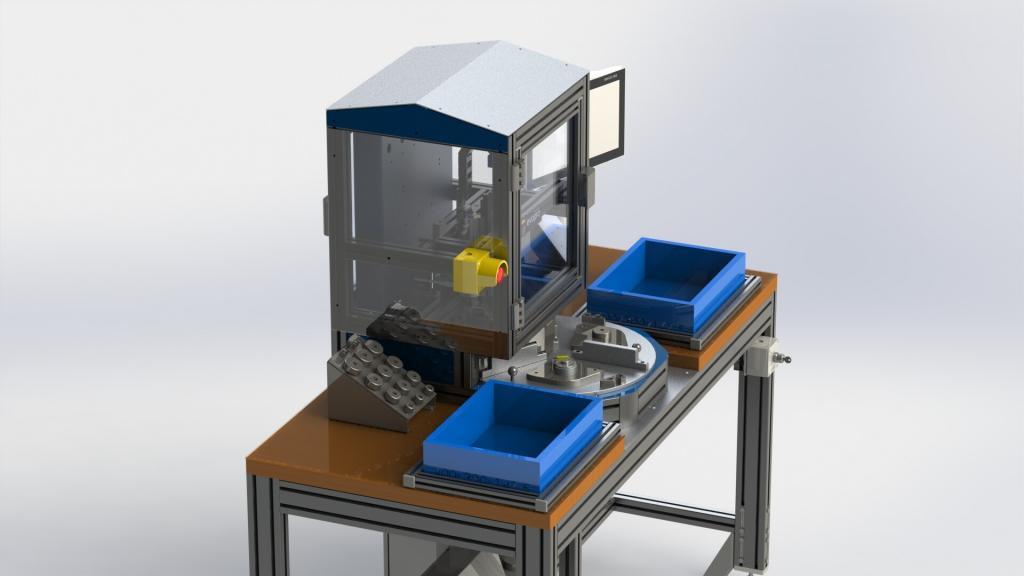

Tapered roller measurement

ABOUT evoChK:

- Measure, rotate, label and visualize

An electric motor manufacturer needs precise information about the dimensions of tapered roller bearings in order to be able to install them more precisely with the help of shims (washers). This precise installation enables optimal power transmission as well as a maximization of the bearing life and thus a reduction in complaints. With evoChK it is now possible to measure the delivered tapered roller bearings to +/- 0.015mm with the help of an optical distance measuring device.

The confocal displacement sensor used works independently of the surface.

To do this, the bearing is placed in the measuring station, rotated by a motor, measured and then labeled. The measured data are visualized on a screen.

Technical overview

Clock speed

35s per bearing

Independent of size

The system can be designed for any size of warehouse

Lettering as desired

Permanent marking with ink jet or marking laser

Visualization of the measurement

Easy integration into existing automation systems